Macro EDM

Precision-Driven EDM Sinker Simulation and Programming Software

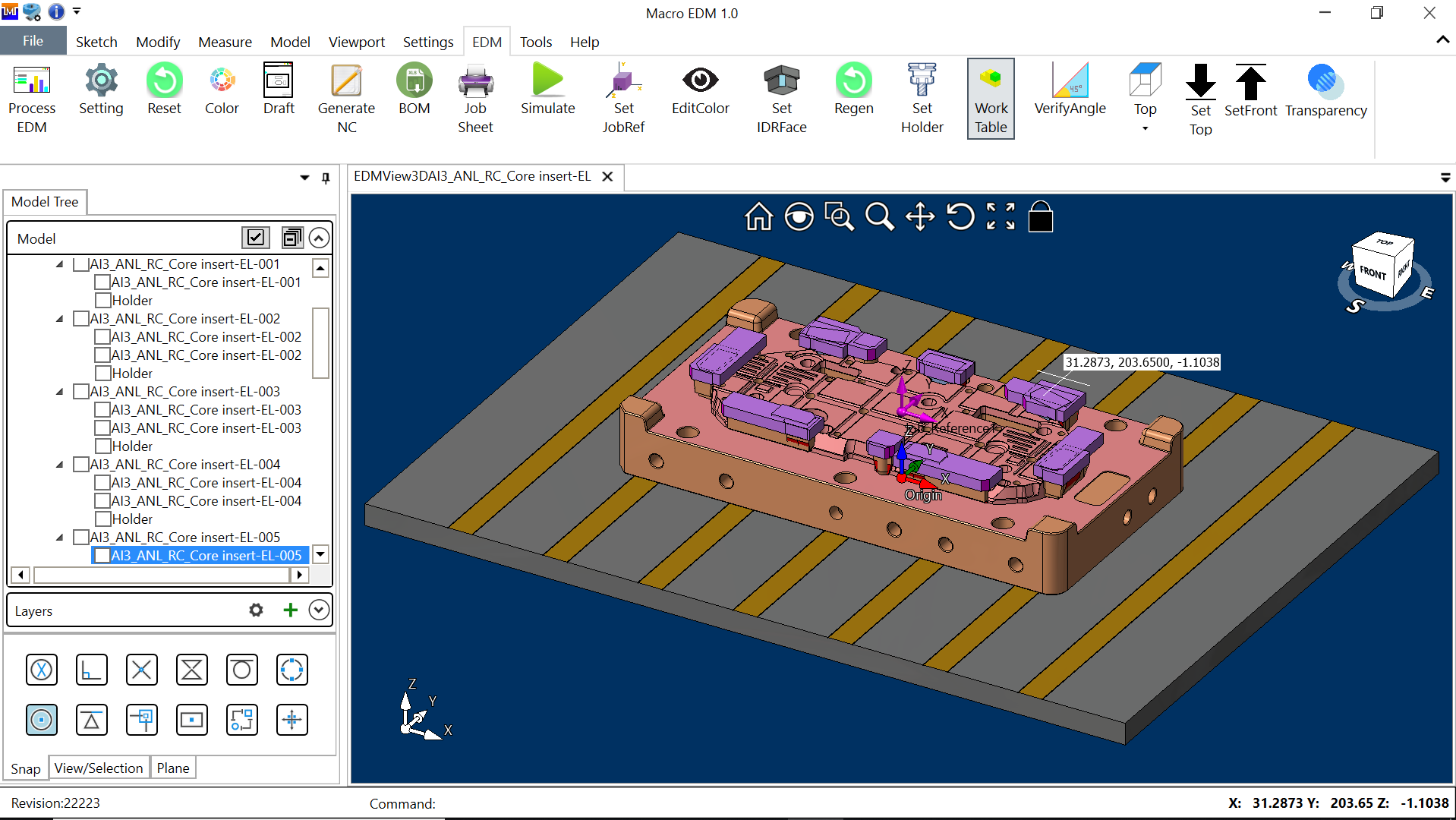

a pioneer in digital manufacturing and CAM software solutions, MACRO EDM is an advanced simulation and programming platform that allows you to plan, simulate, and optimize EDM sinker operations with unmatched accuracy. Whether you’re an EDM engineer seeking fine control or a manufacturing head looking to enhance efficiency and reduce tool wear, MACRO EDM transforms the way EDM processes are planned and executed.

With a user-friendly interface, rich functionality, and compatibility with a wide range of EDM controllers, MACRO EDM bridges the gap between design and machining — ensuring your workshop achieves higher productivity, lower error rates, and superior machining precision.

MACRO EDM is designed for universal compatibility with all major EDM sinker machine brands and controllers, including: +GF+, Mitsubishi, Sodick, Excetek, Chmer, ONA, and Makino. MACRO EDM helps organizations reduce operator dependency and achieve consistency across machines, no matter the brand or age of the controller.

MACRO EDM is a next-generation software that enables simulation, programming, and optimization of EDM sinker machining operations. It gives engineers complete control over machining parameters such as spark gap, current, voltage, pulse duration, and frequency, allowing fine-tuning of every operation for best results.

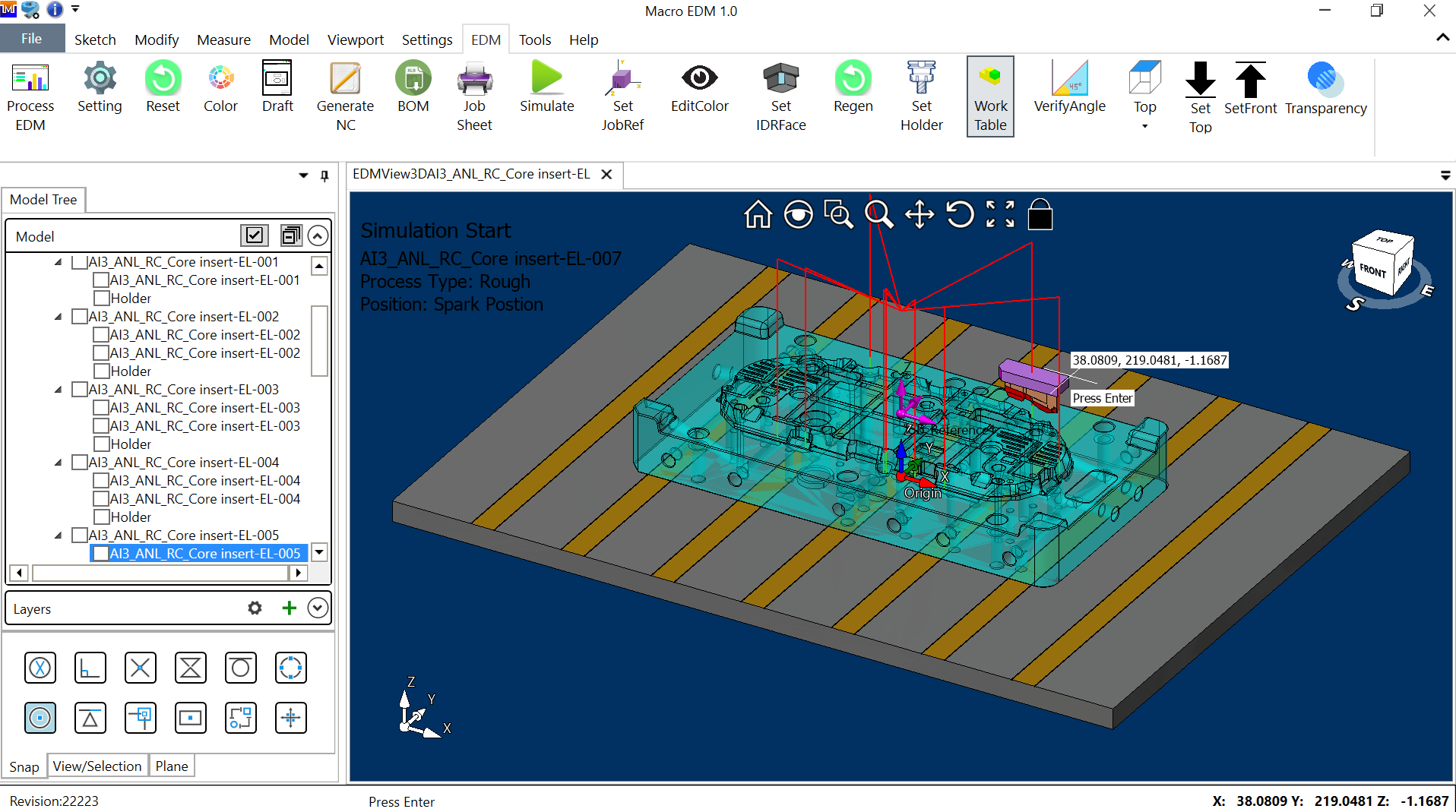

The software supports import of 3D CAD models, provides access to a comprehensive material library, and includes predefined electrode templates — streamlining your workflow from design to NC generation. Its built-in simulation environment allows users to visualize spark erosion, check for collisions, and validate machining paths before execution, significantly reducing setup and test time on actual machines.

MACRO EDM STRATEGIES

MACRO EDM

The software generates ready-to-use NC programs and G-codes optimized for these systems, ensuring a smooth handoff from the virtual workspace to the physical machine. Its post-processor customization enables easy adaptation to specific machine requirements — making it a flexible and reliable companion for diverse EDM setups.

Core Capabilities

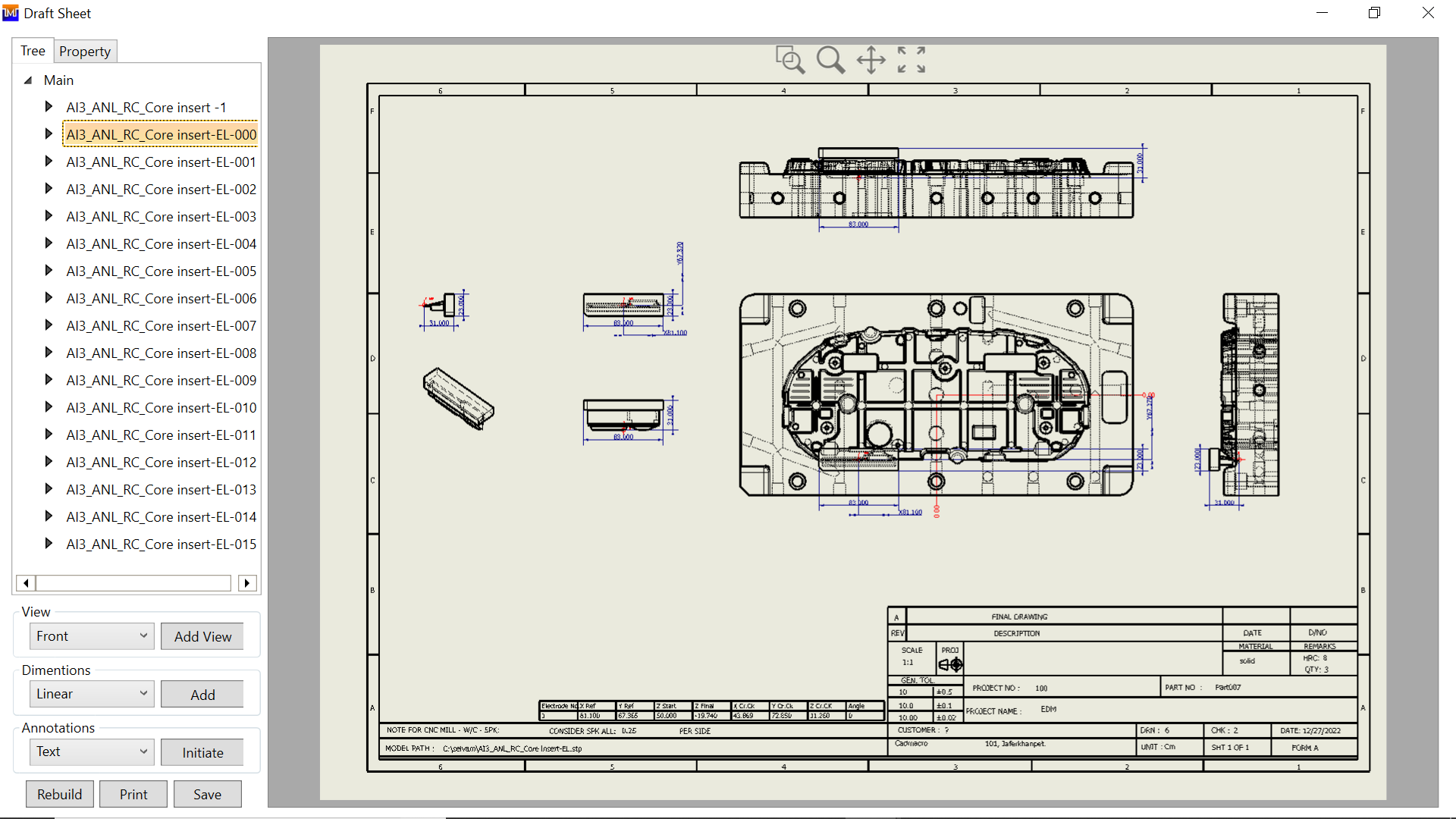

Automated Drafting

Flexible Detailing Templates

2D Auto Detail and Real-Time Simulation

Spark Area and IDR Point Detection

Electrode Position Identification

Taper Matching and Parameter Calling

NC Generation and Tool Offset Control

CMM Data Exchange and Job Sheet Integration

Rotation and Position Detection

Through its virtual spark erosion simulation, users can view material removal, electrode wear, and machining gap evolution. Engineers can tweak machining parameters and instantly see their effects on quality, surface finish, and machining time. This simulation-driven approach eliminates guesswork, enhances predictability, and reduces the number of trial runs required on the shop floor.

The built-in collision detection feature provides added assurance by identifying possible electrode-to-workpiece or fixture collisions before machining starts. This not only protects expensive electrodes and workpieces but also extends machine life and boosts operational safety.

MACRO EDM empowers your tool room with advanced digital capabilities, giving you the confidence to produce superior parts, faster and more efficiently than ever before.

Whether you’re a toolmaker, die designer, or production manager, MACRO EDM provides the perfect blend of simulation accuracy, machining intelligence, and process reliability.

TRIAL REQUEST

Need Help?

Please Feel Free To Contact Us. We Will Get Back To You With 1-2 Business Days.

info@cadmacro.com

(091)-44-4358 9050

SOME OF OUR SUPPORTING

Machines & Post Processor

Here’s how it delivers measurable value:

- Reduced Setup and Programming Time

- Automated drawing, NC generation, and simulation eliminate repetitive manual work — cutting programming time by up to 40–60%.

- Higher Machining Accuracy

- Real-time parameter optimization ensures consistent spark energy, improving accuracy and surface finish quality.

- Lower Electrode Consumption

- By simulating wear and optimizing discharge parameters, MACRO EDM minimizes electrode usage and reduces material costs.

- Reduced Machine Idle Time

- Offline simulation allows engineers to prepare and validate jobs while machines continue running, increasing productivity and equipment utilization.

- Minimized Errors and Rework

- Built-in collision detection, taper control, and automated IDR detection drastically reduce errors, ensuring first-time-right machining.

- Standardized EDM Processes

- Consistent templates, reusable machining strategies, and centralized parameter libraries ensure process uniformity across operators and shifts.

- Complete Process Traceability

- Every job comes with automated reports and NC data tracking, fulfilling quality control and audit requirements effortlessly.