Macro Nest

CNC NESTING SOLUTION

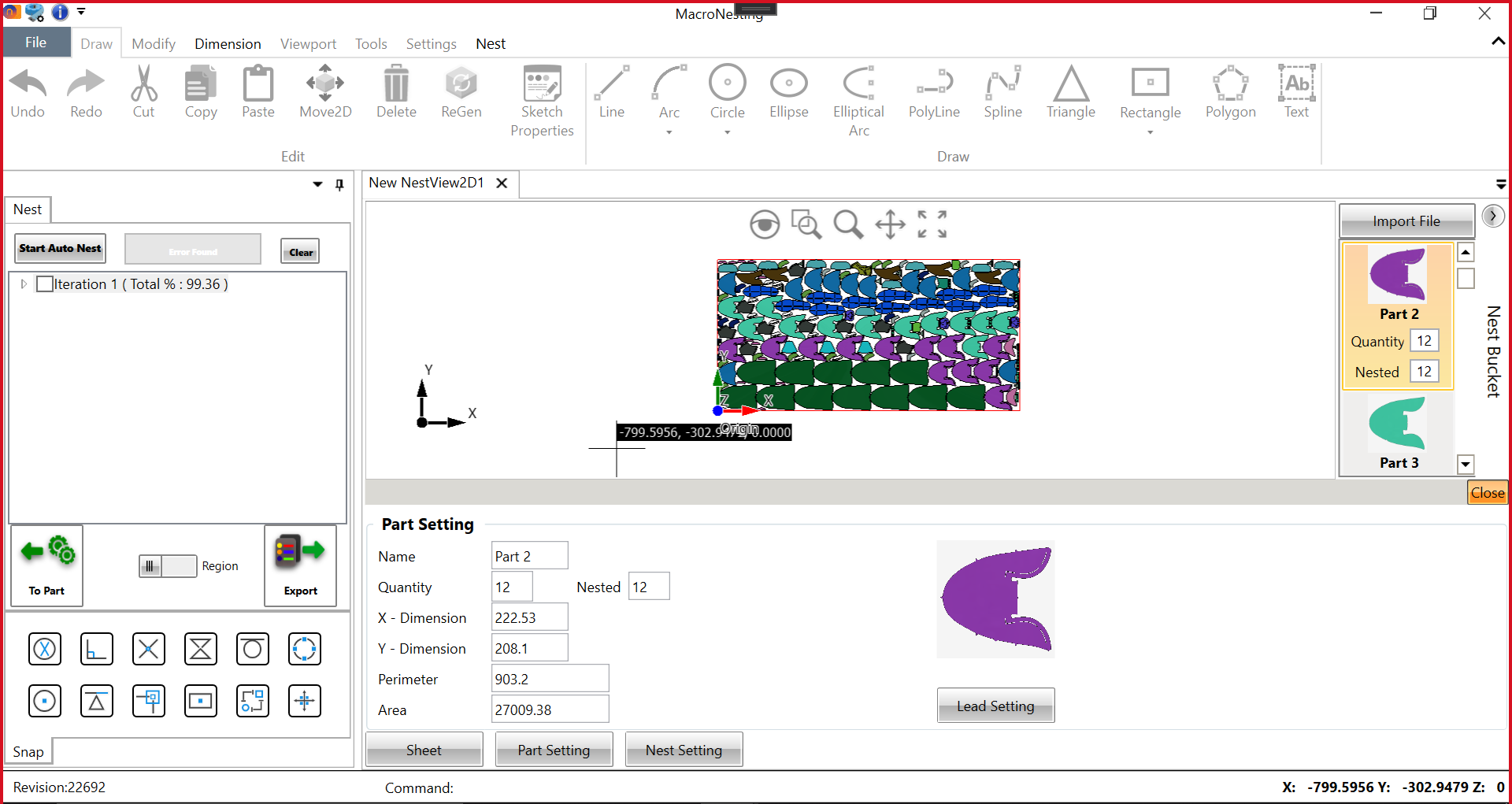

MACRO NEST is a comprehensive and innovative CNC solution for your sheet metal nesting needs. It will help you reduce material waste, increase productivity, improve quality, and save money. You don’t have to worry about errors or inconsistencies in your drawings, as MACRO NEST can automatically detect and fix them for you. Macro Nest allows you to edit and simulate your NC code before sending it to your machine, to ensure that everything is correct and avoid costly mistakes. You can generate a detailed report of your nesting job, including material usage, cutting time, cost, and efficiency.

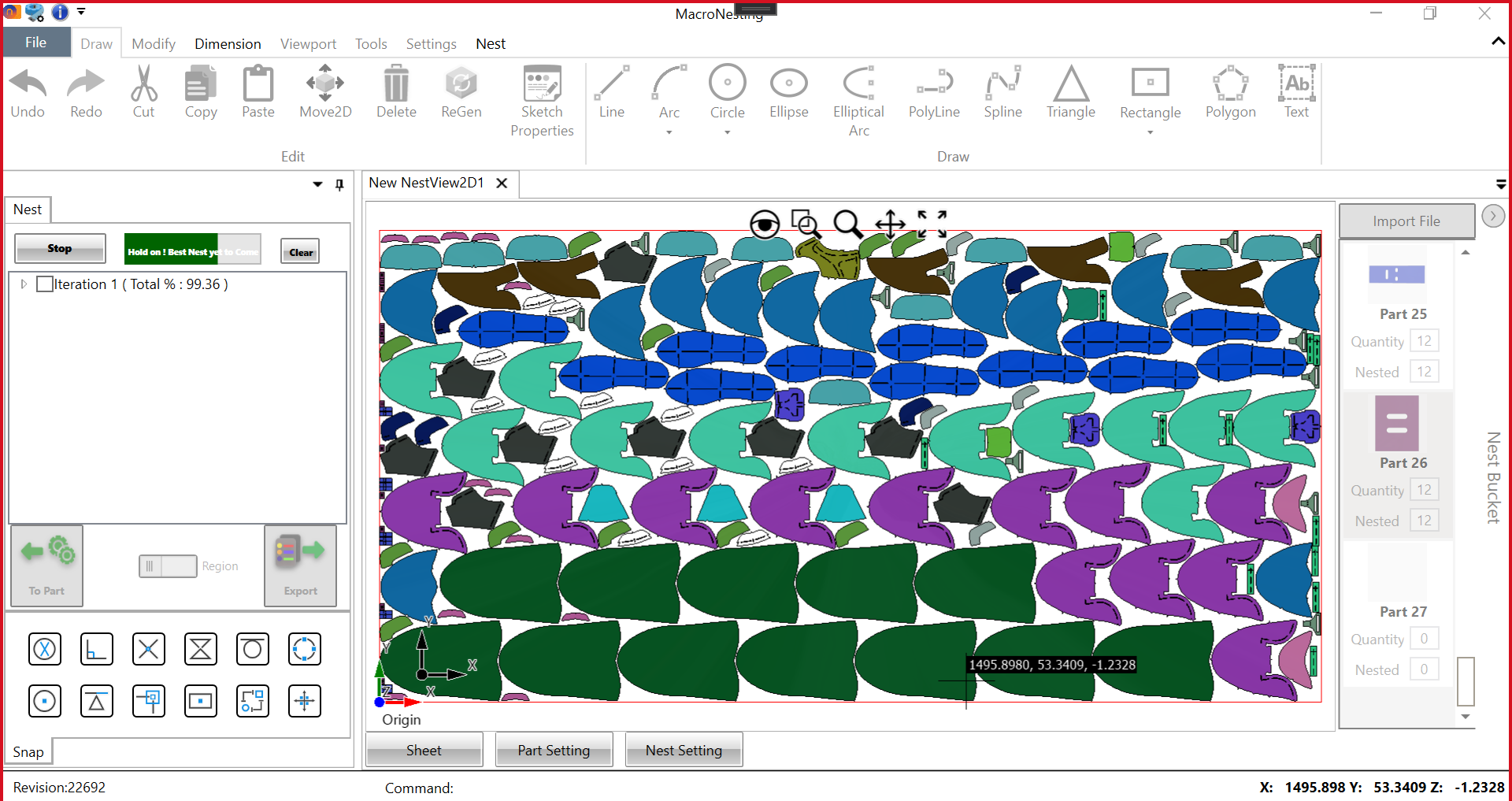

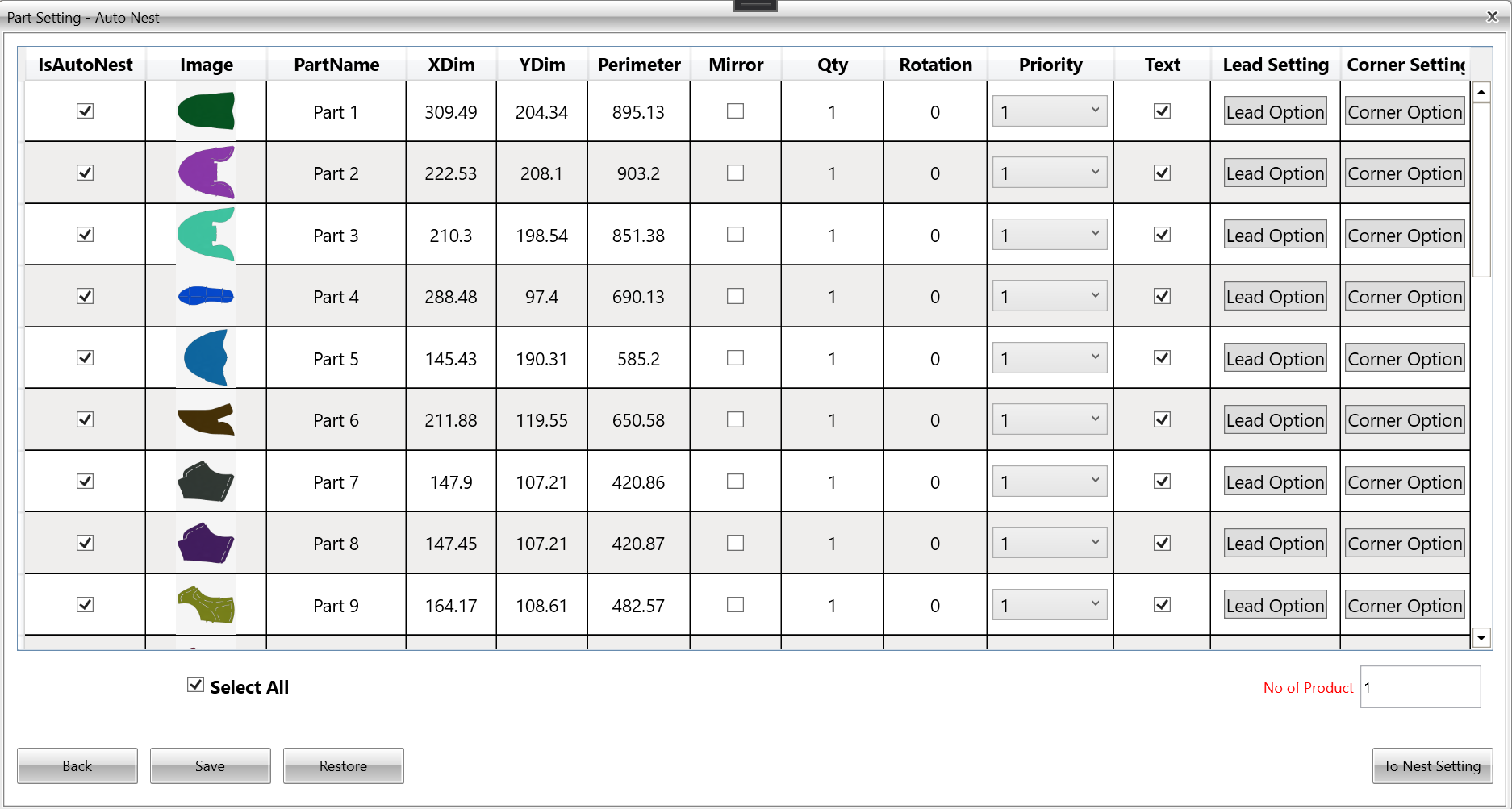

Macro Nest can choose the best approach for each operation, based on your machine capabilities. Automatic micro-joints, lead-ins/outs, loops etc. Interactive nesting gives you the flexibility to nest your parts in different ways, such as arrays, bump nesting free hand and mosaic nesting. You can also customize your machine commands for different operations, such as repositioning, parting, unloading and skeleton destruction.

It can also sequence your final cuts in the most efficient order. You can integrate MACRO NEST with your existing ERP system, to streamline your workflow and manage your inventory, orders, and production.

.

MACRO NEST STRATEGIES

MACRO NEST

- It supports various cutting technologies, such as plasma, laser, waterjet, etc.

- It can handle complex shapes and geometries with ease.

- It can automatically optimize the cutting path and sequence to minimize changes and movements.

- It can work with different sheet sizes and thicknesses.

- Supporting DXF/DWG

- Auto Fix

- Extended ERP Approach

- NC Editor

- Simulation

- Nesting Job Sheet

- Robust Placement Parameters

- Regular Sheet Support

- Multiple Project Handling

- Tab Features

- Cooling Stops

- Manual Nesting

- Various Approaches

- Cut Sheet assignment

TRIAL REQUEST

Need Help?

Please Feel Free To Contact Us. We Will Get Back To You With 1-2 Business Days.

info@cadmacro.com

(091)-44-4358 9050

SOME OF OUR SUPPORTING

Machines & Post Processor