Macro Turn

CNC TURNING SOLUTION

MACRO TURN is CADMACRO’s next-generation CNC Turning Solution, purpose-built to meet the evolving needs of modern machine shops and tool rooms. It provides a complete digital environment where complex turning operations are simplified, programming becomes more intuitive, and machining productivity is significantly enhanced.

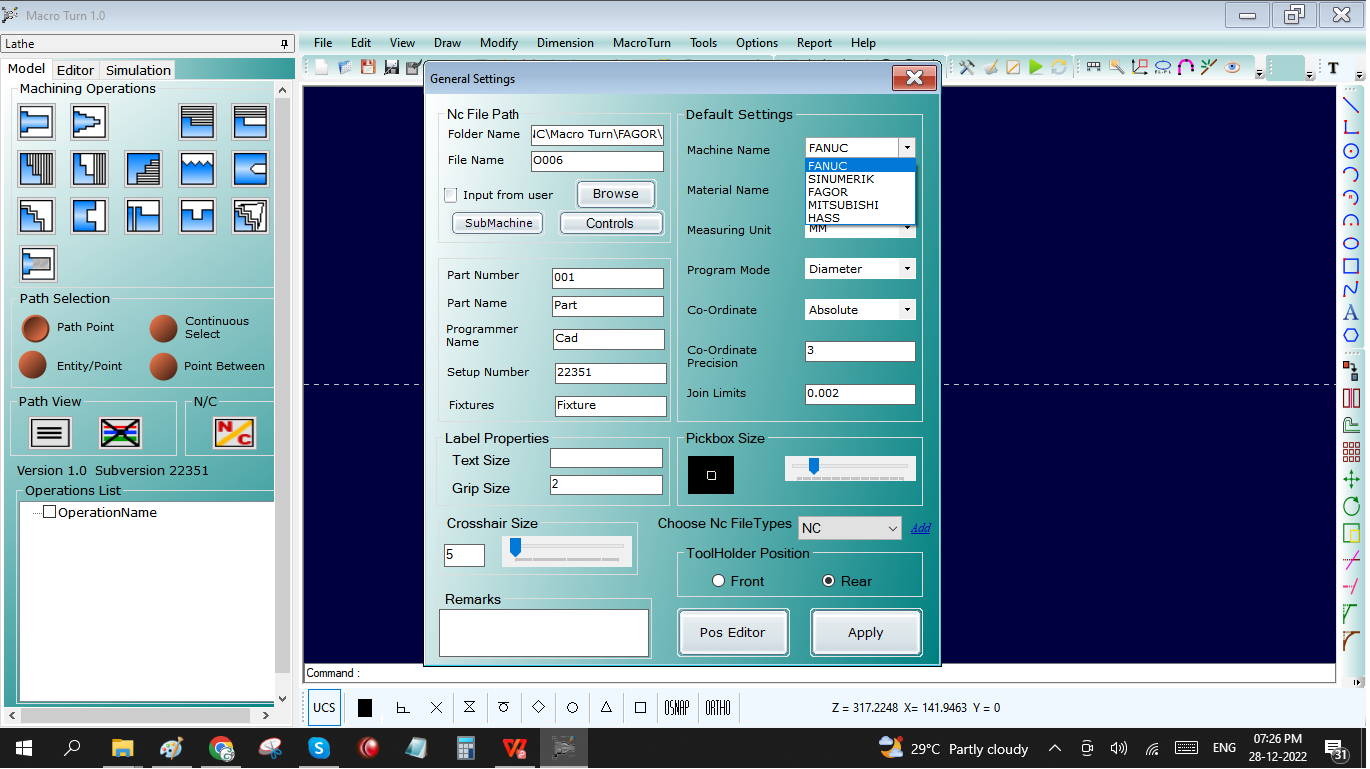

One of the best features of Macro Turn is its user-customizable post processor, which gives you the flexibility to support different types of machines such as SIEMENS, FAGOR, MITSUBISHI, FANUC, HEIDENHAIN , OKUMA, SINUMERIC, HAAS & etc. You can configure the post processor using the built-in NC config feature, which allows you to output programs very close to or exactly the way you want.

Designed with the principle of precision through intelligence, MACRO TURN integrates advanced programming tools, powerful simulation capabilities, and optimization features that ensure every part is manufactured right the first time. From basic turning and facing to intricate multi-start threading, spiral machining, and groove finishing, MACRO TURN delivers comprehensive functionality that covers the full spectrum of CNC turning applications.

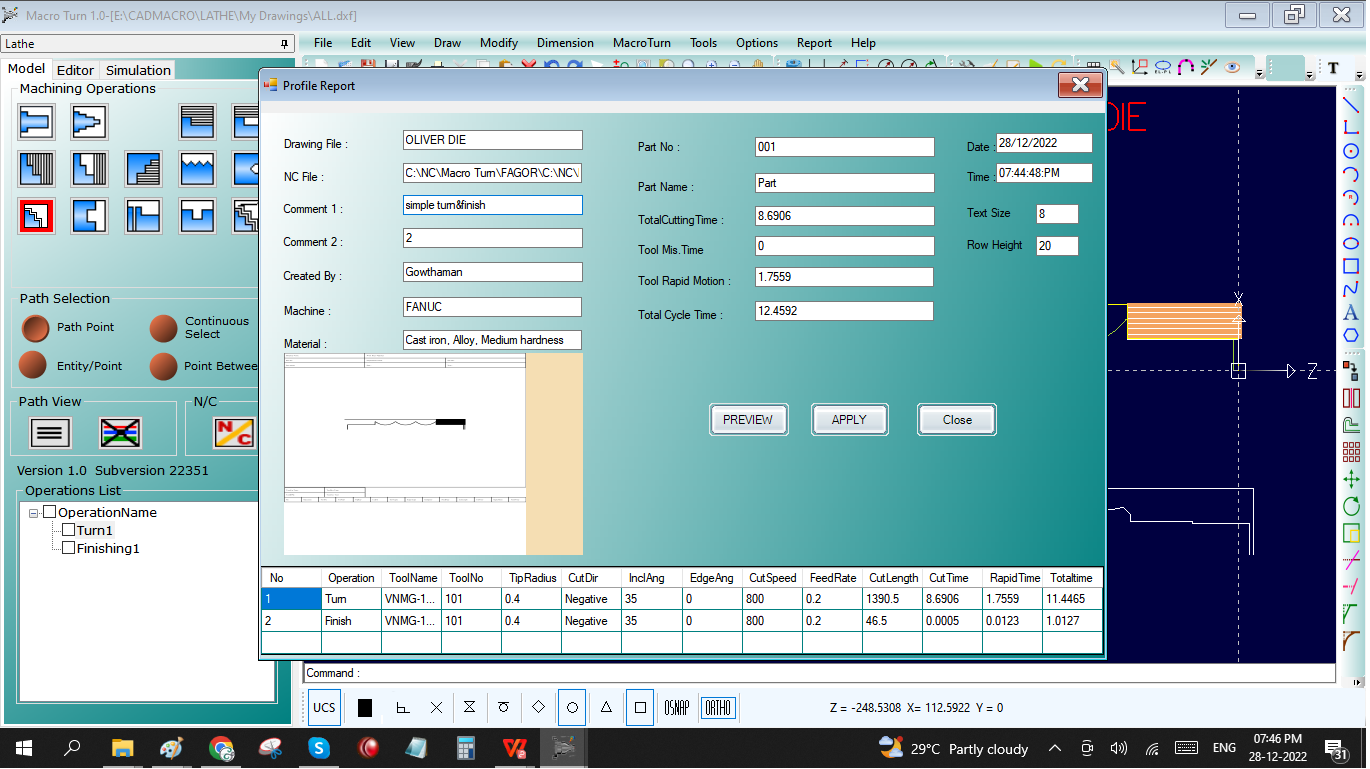

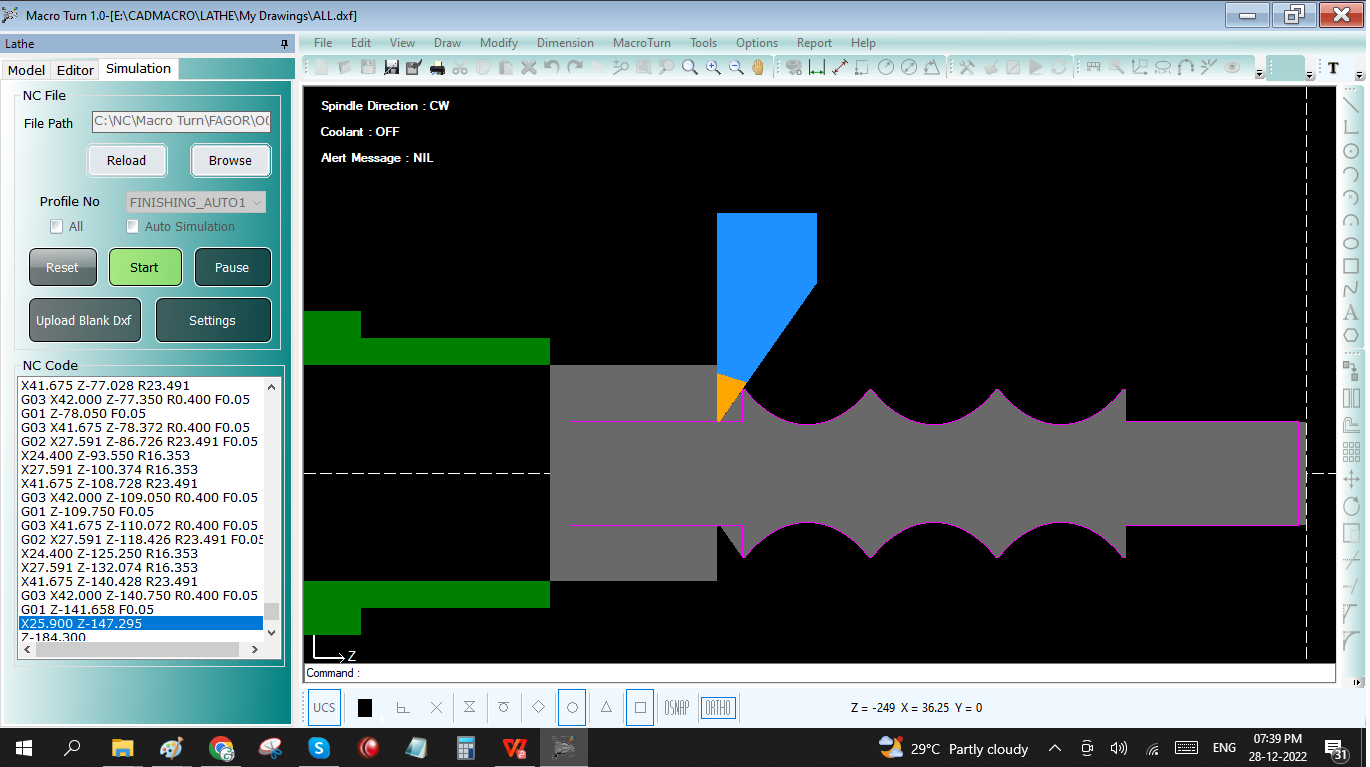

By connecting design-to-manufacturing workflows, MACRO TURN bridges the critical gap between CAD/CAM systems and the physical shop floor. Engineers can easily edit CAD geometry, select tools from an integrated library, and generate optimized NC programs with automatic tool nose compensation and accurate cycle time estimation. Operators benefit from detailed job sheets, real-time simulation, and collision detection that minimize errors and downtime.

Why Choose MACRO TURN?

- Faster programming with reduced setup time

- Enhanced machining accuracy and surface finish

- Comprehensive tool & insert database

- Simulation-driven error-free production

MACRO TURN STRATEGIES

MACRO TURN

Macro Turn supports both cycle programs and normal programs. Cycle programs are predefined sequences of operations that can be executed with a single command. Normal programs are custom sequences of operations that can be written by the user. Macro Turn also provides a job sheet that summarizes all the parameters and settings for each operation. You can easily edit, save, and print your job sheet for future reference.

- Turning, Facing, Drilling, Grooving

- External & Internal Threading

- Parting, Knurling & Bar Pulling

- Ball & Spiral Machining

- Boring & Back Boring

- Open Profile Machining with high accuracy

- Programming & Productivity Tools

- Cycle & Normal Programs

- Full Simulation with Collision Check

- Quill Call & Return

- NC Editor – Quick code editing and customization

- Job Sheet Generator – Automated documentation

- Cycle Time Calculation – Accurate machining time

- Smart Features & Libraries

- CAD Editing – Direct geometry modification for faster setups

- Tool & Insert Libraries – Ready-to-use database

- Auto Tool Nose Compensation

- Groove Finishing in Multiple Directions

- Enhanced surface finish and accuracy

TRIAL REQUEST

Need Help?

Please Feel Free To Contact Us. We Will Get Back To You With 1-2 Business Days.

info@cadmacro.com

(091)-44-4358 9050

SOME OF OUR SUPPORTING

Machines & Post Processor