Macro Wire - Advanced Wire Cut CAM Software for Precision and Productivity

Macro Wire is a comprehensive, intelligent, and high-performance CAM solution designed specifically for Wire EDM (Electrical Discharge Machining) professionals. It empowers wire cut engineers to handle any complexity of wire cut projects with unmatched precision, efficiency, and flexibility.

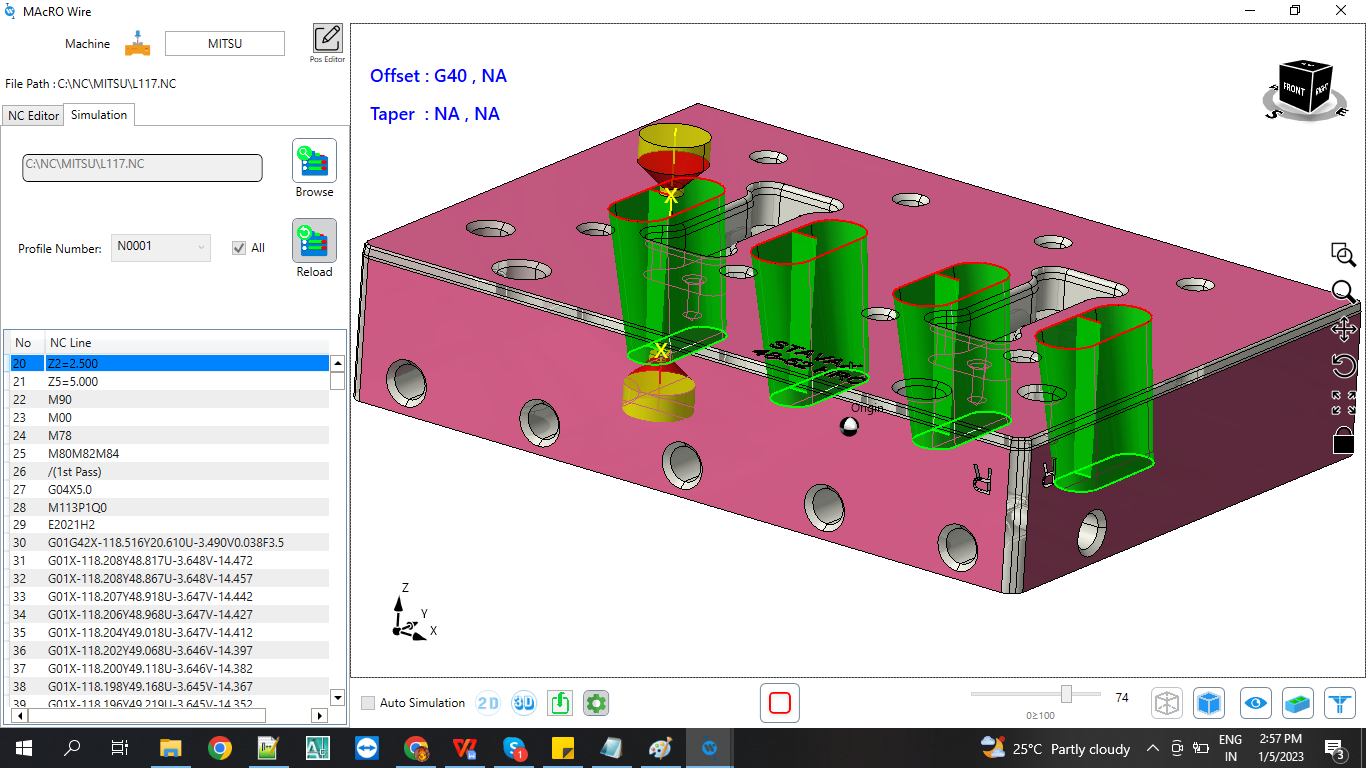

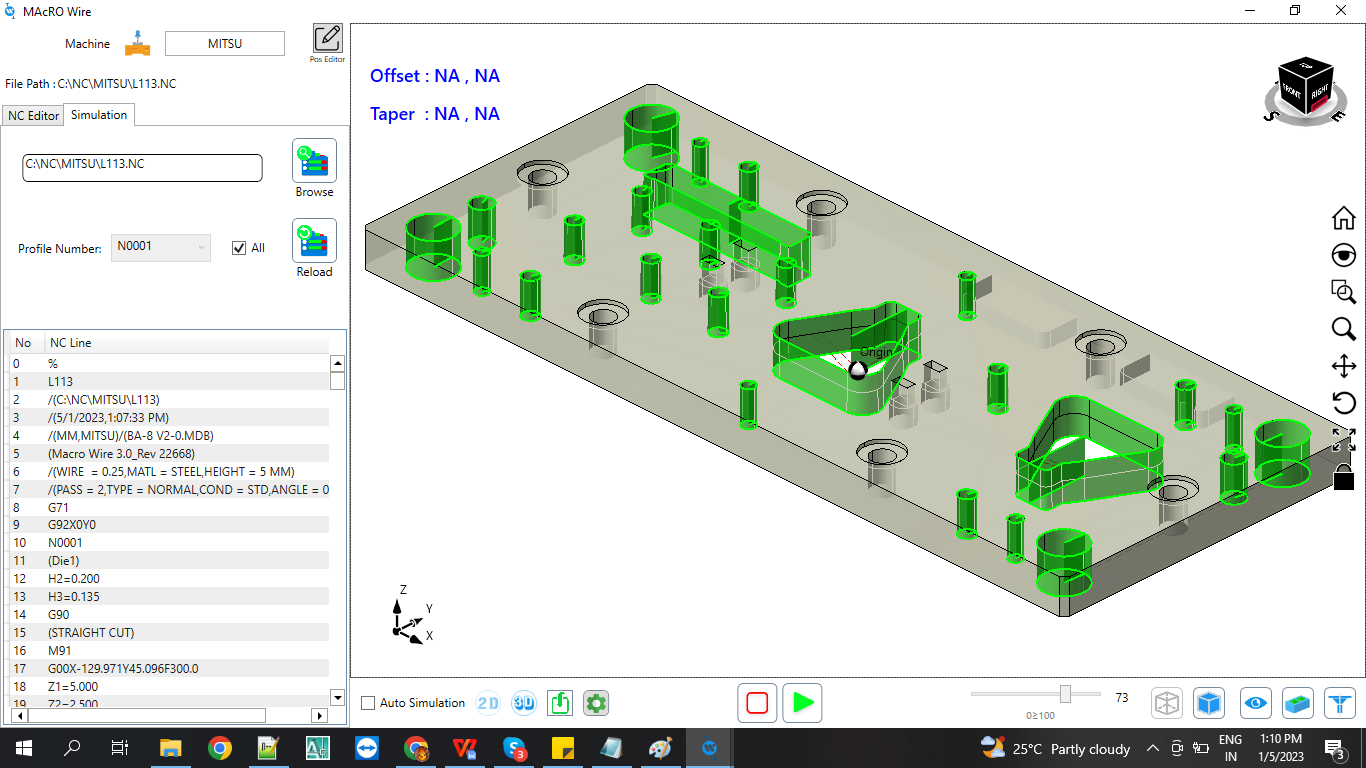

Whether you’re programming for 2D, 3D, or multi-axis Wire EDM operations, Macro Wire delivers everything you need—from CAD modeling to toolpath generation and post-processing—in one seamless environment.

Why Choose Macro Wire?

Macro Wire is the perfect companion for modern wire cut engineers who aim to maximize productivity, ensure accuracy, and reduce programming time. Its powerful features and user-friendly interface are built to handle every stage of your workflow—design, setup, simulation, and output—while maintaining full control over machining parameters and cutting strategies.

Macro Wire offers complete flexibility with post-processing. You can create and customize your own post processors to match the specific requirements of any wire cut machine.

The platform supports a wide range of popular EDM brands, including:

+GF+, MITSUBISHI, MAKINO, SODICK, YCM, EXCETEK, ACCUTEX, JOEMARS, CHMER, AGIE, CHARMILLES (ROBOFIL), FANUC, HITACHI, ELECTRONICA, ONA, JAPAX, ACT SPARK, ARD, SPM, and many others.

Each post processor can be configured to output NC programs exactly the way you need them, ensuring smooth integration with your existing shop floor setup.

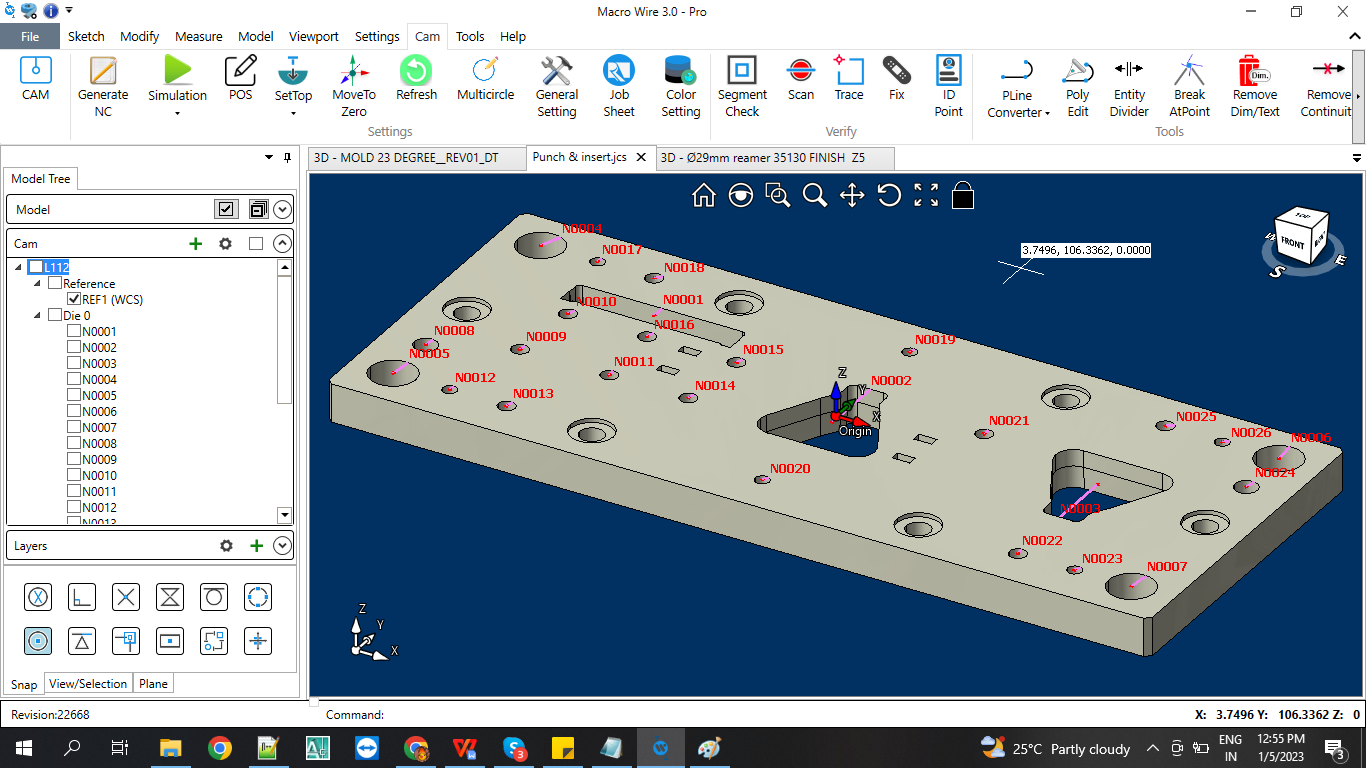

A Complete CAD/CAM Environment for Wire Cut

Macro Wire includes a powerful 2D/3D CAD system tailored for wire cutting applications. It’s designed for speed, accuracy, and ease of use, allowing engineers to design, modify, and prepare parts effortlessly—from simple inserts to complex multi-axis profiles.

Key highlights include:

-

Intuitive Drafting Tools – Fast and precise 2D/3D sketching for wire EDM geometries.

-

Smart Import & Edit – Import, modify, replicate, or rotate 3D models easily.

-

Flexible Programming – Supports 4-axis manual and auto mapping, as well as 6-axis cutting with probing.

-

Advanced Strategy Control – Define, save, and reuse cutting strategies for consistent performance.

MACRO WIRE STRATEGIES

MACRO WIRE

Macro Wire provides a library of predefined cutting strategies optimized for different materials, wire types, and machining conditions. You can also customize or create your own strategies, enabling process standardization and quick setup for repeat jobs.

- 2D/3D Drafting / Sketching

- 4 Axis Manual / Auto Mapping

- Unman Cutting

- Insert Cutting

- Punch, Die, Open Profile Cutting

- Similar Hole / Color / All Selection

- Chipless, Gear Drafting

- Import / Modify / Replicate / Rotate

- 3D Model, 6th Axis Program Auto Fix

- 6 Axis Cutting With Probing

- Hole Listing / Identification

- Pre Defined Strategy

- Vast Parameter Database

- Multi Hold Cutting

- Multi POS processor

- Multi Hold POS Setting Simulation

- Job Report

TRIAL REQUEST

Need Help?

Please Feel Free To Contact Us. We Will Get Back To You With 1-2 Business Days.

info@cadmacro.com

(091)-44-4358 9050

Automation, Flexibility & Accuracy

Macro Wire automates many repetitive tasks such as hole listing, mapping, parameter assignment, and multi-position simulation—reducing human error and ensuring consistent quality. Engineers can easily validate their setups using realistic cutting simulations before running on the machine, saving valuable time and resources.

Macro Wire Advantages at a Glance

-

✅ Comprehensive 2D/3D CAD/CAM Integration

-

✅ Custom Post Processor Builder

-

✅ Multi-Axis Support (4th, 5th, 6th Axis)

-

✅ Automatic Strategy Selection

-

✅ User-Friendly Interface

-

✅ Complete Job Reporting and Traceability

-

✅ Compatible with All Major EDM Machines

Experience the Power of Precision

Macro Wire redefines Wire EDM programming with its combination of automation, adaptability, and accuracy. Whether you’re running a small tool room or a large production facility, Macro Wire gives you the edge to deliver superior quality, reduced lead time, and optimized productivity.

SOME OF OUR SUPPORTING

Machines & Post Processor